Micro turbine jet engines are rapidly becoming one of the most exciting propulsion technologies in the UAV, RC aviation, and research sectors. With compact size, high thrust-to-weight ratios, and impressive reliability, they have moved far beyond the hobby market and are now widely used by UAV manufacturers, R&D institutions, aerospace startups, and professional RC jet builders.

From 2025 to 2030, the global demand for 40–150 kgf class micro turbine engines is projected to grow at a strong rate. As new applications continue to emerge—ranging from high-speed UAV platforms to experimental airframes and advanced technical education—the importance of choosing the right turbine engine supplier has never been greater.

This article provides a complete guide for B2B buyers, engineering teams, OEM partners, and distributors who are planning to integrate micro turbine engines into their projects.

1. Why Micro Turbine Jet Engines Are Entering a High-Growth Period

The micro turbine market is experiencing strong momentum, driven by several key factors:

1.1 Rising global UAV development

Commercial and industrial UAV platforms increasingly require higher thrust, longer endurance, and better payload capacity. Micro turbines provide strong power output in a compact configuration, making them ideal for:

-

High-speed fixed-wing UAVs

-

Target drones and experimental aircraft

-

Long-range R&D test platforms

-

Jet-assisted takeoff (JATO) UAV systems

1.2 Growth of large-scale RC jet aviation

RC super-jets, scale model projects, and competition aircraft are more popular than ever. Professional builders now look for engines in the 40–150 kgf range with:

-

Stable ECU

-

Smooth throttle response

-

Strong durability

-

Global serviceability

1.3 Research & engineering education demands

Universities, aerospace labs, and engineering institutes increasingly incorporate micro turbine engines into:

-

Propulsion research

-

CFD & flight dynamics testing

-

Experimental aircraft programs

-

Engine performance labs

-

Student design competitions

1.4 Supply chain maturity in China

As manufacturing capabilities grow, high-quality micro turbine engines have become more accessible. Suppliers offering OEM/ODM customization and batch delivery are now deeply integrated into the global B2B UAV ecosystem.

2. Micro Turbine Jet Engine Fundamentals — What B2B Buyers Must Know

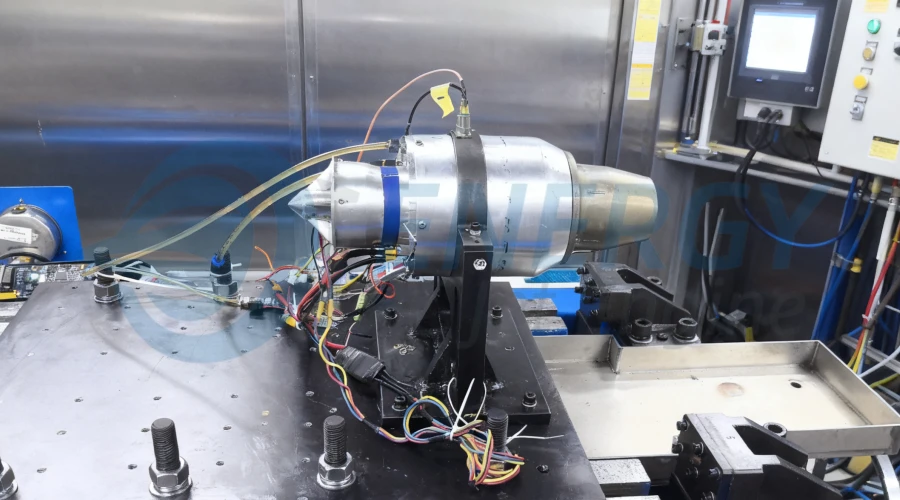

Before selecting an engine, it’s helpful to understand the core components that determine performance and reliability.

2.1 How a micro turbine engine works

Although much smaller than full-scale jet engines, micro turbines operate on the same principle:

-

Air intake

-

Compressor stage (centrifugal or axial)

-

Combustion chamber

-

Turbine wheel

-

High-velocity exhaust producing thrust

This simple yet powerful design enables impressive performance even at compact sizes.

2.2 Key performance parameters

For engineering teams evaluating engines, focus on:

-

Thrust output: 40 kgf to 150 kgf for UAV & RC jets

-

Weight: affects aircraft payload and CG placement

-

Fuel efficiency: directly impacts endurance

-

ECU system: stability, safety protections, parameter tuning

-

Throttle response: critical for maneuverability and takeoff

-

Operating reliability: vibration, heat resistance, rotor balancing

-

Maintenance & serviceability: access to spare parts, diagnostics

2.3 Why micro turbines outperform other propulsion systems

Compared to electric propulsion, micro turbines offer:

-

Much higher thrust density

-

Higher cruise speed

-

Better endurance for large airframes

-

Greater payload capacity

-

Better suitability for long-distance missions

This is why they are increasingly used in industrial UAVs, target drones, and next-gen experimental aircraft.

3. 2025–2030 Market Trends in Micro Turbine Jet Engines

3.1 Strong forecasted market expansion

Market research shows sustained growth for micro turbine engines through 2030, driven by:

-

Military and commercial UAV R&D

-

Rapid rise of global RC aviation communities

-

Increased investment in experimental aerospace programs

-

Wider availability of high-performance engines with 40–150 kgf thrust

3.2 Growing demand for specialized engines

Manufacturers and institutions increasingly require:

-

Higher thrust ranges

-

Customized fuel systems

-

Advanced ECU monitoring

-

Improved durability under harsh environments

-

Tailored mounting solutions

-

Batch production for commercial UAV programs

This shift from hobby to industrial application significantly increases the expectations for performance and reliability.

3.3 The “OEM era” of micro turbines

The industry is clearly transitioning toward:

-

OEM-integrated propulsion systems

-

Engine-airframe compatibility design

-

Custom electronics and interface configurations

-

Application-specific performance tuning

This creates opportunities for suppliers who can deliver high-quality engines with customization flexibility.

4. How to Choose the Right Micro Turbine Jet Engine Supplier

Selecting an engine is not only about thrust; it’s about long-term reliability, support, and engineering compatibility.

Below is a checklist for evaluating suppliers (ideal for procurement teams and system engineers).

4.1 Full thrust range availability (40–150 kgf)

A serious supplier should offer a family of engines suitable for:

-

Medium-size UAVs (40–60 kgf)

-

Large RC jets (80–120 kgf)

-

Heavy-lift or high-speed UAVs (120–150+ kgf)

A wide portfolio ensures better matching between engine and aircraft.

4.2 Manufacturing quality & materials

High-quality engines use:

-

CNC-machined components

-

Aviation-grade alloys

-

High-temperature combustion liners

-

Precision rotor balancing

-

High-speed ceramic hybrid bearings

These factors directly influence reliability and lifespan.

4.3 ECU stability & control systems

A robust ECU is essential for B2B operational scenarios. Key capabilities include:

-

Automatic start sequence

-

Real-time temperature & RPM monitoring

-

Fuel pump control

-

Safety shutdown logic

-

Smooth, predictable throttle mapping

For UAVs, an ECU with digital interface ports is a must.

4.4 Customization (OEM / ODM)

Professional buyers often require:

-

Custom thrust tuning

-

Modified mounts

-

Tailored fuel systems

-

Communication interfaces

-

Airframe-specific exhaust geometry

Suppliers who support customization provide a major advantage for engineering teams.

4.5 Documentation, testing, and certification

Reliable suppliers provide:

-

Test reports

-

Performance curves

-

Installation manuals

-

Safety guidelines

-

Endurance test documentation

Especially important for university labs, industrial UAVs, and aerospace research.

4.6 Global logistics & after-sales service

For B2B buyers, support matters just as much as performance:

-

Spare parts availability

-

Response speed

-

Technical troubleshooting

-

Warranty terms

-

Batch delivery capacity

This ensures long-term project stability.

5. Real-World Application Scenarios

Micro turbine jet engines are used in a wide range of professional applications worldwide.

5.1 UAV / Unmanned Aircraft Systems

-

High-speed UAVs

-

Experimental test platforms

-

Target drones

-

Long-range fixed-wing airframes

-

VTOL assist systems

5.2 Academic & Research Institutions

-

Propulsion research & lab testing

-

Jet engine thermodynamics studies

-

Student aerospace competitions

-

Prototype and CFD validation

5.3 Large RC Jet Aircraft

-

Super-scale RC models

-

Airshow performance jets

-

Competition aircraft

-

Club-level high-performance builds

5.4 OEM / Distributors

-

Batch purchasing

-

Branded propulsion packages

-

Engine integrated into proprietary airframes

-

Commercialized UAV propulsion systems

With thrust levels between 40–150 kgf, the possibilities are extensive.

6. B2B Procurement Checklist (Quick Summary)

Before purchasing, ensure your supplier provides:

-

✔ A suitable thrust range (40–150 kgf)

-

✔ High-quality CNC components and rotor balancing

-

✔ Strong ECU reliability and digital interface options

-

✔ OEM/ODM customization capability

-

✔ Clear testing documentation

-

✔ Fast global delivery

-

✔ Warranty & reliable after-sales service

A reliable supplier should function as a long-term engineering partner, not just a vendor.

7. Conclusion — Why Now Is the Best Time to Invest in Micro Turbine Jet Engines

From 2025 to 2030, micro turbine jet engines will play a transformative role in professional UAV development, large-scale RC aviation, research programs, and emerging aerospace concepts.

Organizations that secure dependable engine suppliers—offering customization, technical support, and wide thrust ranges—will gain a competitive advantage in performance, reliability, and operational cost.

Energy RC Jet Engine provides:

-

Full 40–150 kgf turbine engine series

-

OEM/ODM customization

-

Application-specific engineering support

-

Global B2B delivery and technical cooperation

For quotations, partnerships, or technical consultation, feel free to contact our team.

We look forward to supporting your next-generation UAV, research, or RC jet propulsion project.